Kalmar helps develop sustainable, autonomous ports

Kalmar is participating in the EU-funded AEGIS project to build the next generation of sustainable and competitive logistics systems for smaller ports.

Europe’s biggest ports are amazing places, efficiently moving enormous amounts of materials that modern societies require. Yet, Europe also has many smaller ports which play just as critical a role.

The Advanced, Efficient and Green Intermodal Systems (AEGIS) is a three-year, €7.5 million project funded by the EU’s Horizon 2020 Research and Innovation programme. It is developing the smaller ships, routes and terminals which are an important component of Europe’s logistics network. Many containers are currently transported by truck, but if some of this could be moved through waterways, we would reduce road congestion and improve sustainability with more efficient ships and barges. The AEGIS use cases include the Port of Trondheim in Norway, inland waterways in the Benelux countries, and the Ports of Aalborg and Vordingborg in Denmark.

“AEGIS will help develop autonomous ships and automation in smaller ports,” explains Pia-Liisa Vuorela, Product manager, Automation at Kalmar. “We have delivered automation solutions to many larger ports, but we need to think about these smaller ports, too.”

Kalmar constantly searches for opportunities to develop new technologies and processes to improve safety, sustainability, efficiency and productivity in cargo handling. Kalmar wanted to participate in the AEGIS project as it would be a perfect venue to co-create solutions beneficial to all their customers.

Environmental benefits of automation

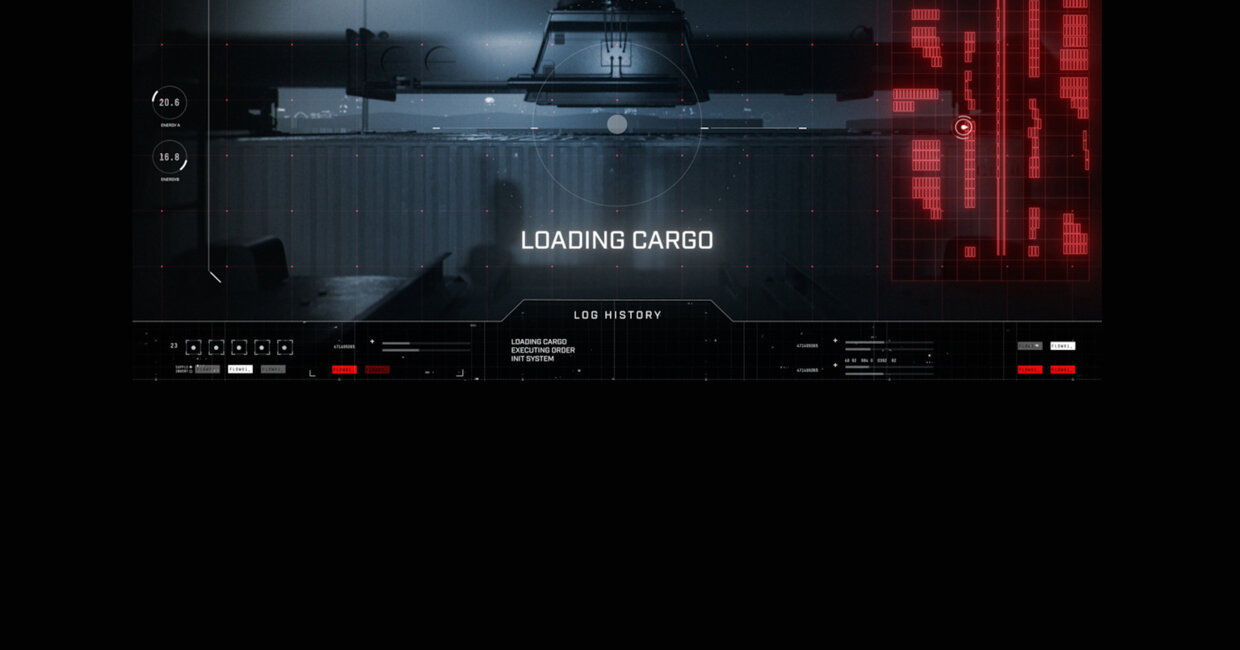

Kalmar has a range of automation offerings such as automated straddle and shuttle carriers. Additionally, the company is investing in the development of robotised, autonomous equipment that will be able to address the needs of all types of facilities, from smaller container terminals to diverse load handling requirements in industrial settings.

Automation is highly attractive due to its long list of benefits which can directly impact profits, including increased safety, efficiency, predictability and flexibility. Automation and robotics can also be a major boost to sustainability.

“Automation and robotics can help to support sustainability in several ways,” explains Tommi Pettersson, VP Strategy, Sustainability and Technology at Kalmar. “It increases efficiency which lowers energy consumption. Automation and robotics can also increase safety. Automated machines are quieter, which is particularly important for urban areas. Although electric vehicles were not the sole focus of AEGIS, Kalmar has developed great EVs which are perfect for automating smaller ports.”

Automation is increasing rapidly throughout the waterborne logistics network, but to date most of the improvements have gone to large the ports, not the small ones.

“Small ports don’t have the same infrastructure and equipment as megaports,” Vuorela continues. “Most of the equipment is mobile. A small port might only have one reachstacker and one terminal tractor. A port might not even have a crane, but instead depend on cranes on vessels.”

Co-creation of the best solutions

Sophisticated robotic solutions for small ports aren’t developed in a vacuum. Kalmar works closely with a range of partners in the AEGIS project, including research institutes SINTEF Ocean and ISE, logistics companies DFDS and NCL, Aalborg University and the Technical University of Denmark, software firm Grieg Connect, and the Ports of Aalborg, Vordingborg and Trondheim. Kalmar’s sister company MacGregor is also participating as a technology provider.

“It is great working so closely with the ports and other organisations to better understand exactly what they need,” says Vuorela. “For over three years we have been building strong relationships.”

“By working with our partners we have developed a blueprint for automating a smaller terminal which is applicable to other customers,” Pettersson adds. “We have also been able to compile hard data to confirm the benefits of these solutions.”

Kalmar continuously develops eco-efficient solutions to support their customers’ sustainability journey, but the AEGIS project has accelerated the pace of development of small port automation and sustainability, so Kalmar’s customers will see more benefits sooner.

“Next, we are building prototypes, verifying automation designs and simulating operations,” says Vuorela. Already today, prototypes of Kalmar RoboTractor, an autonomous terminal tractor, are currently being tested at different Kalmar and customer sites around the world.

We have proven the need and the value of this and our confidence in mobile equipment automation continues to grow.”